2 Stroke Connecting Rod Failure

I can t think of one ever built with a pressure fed big end.

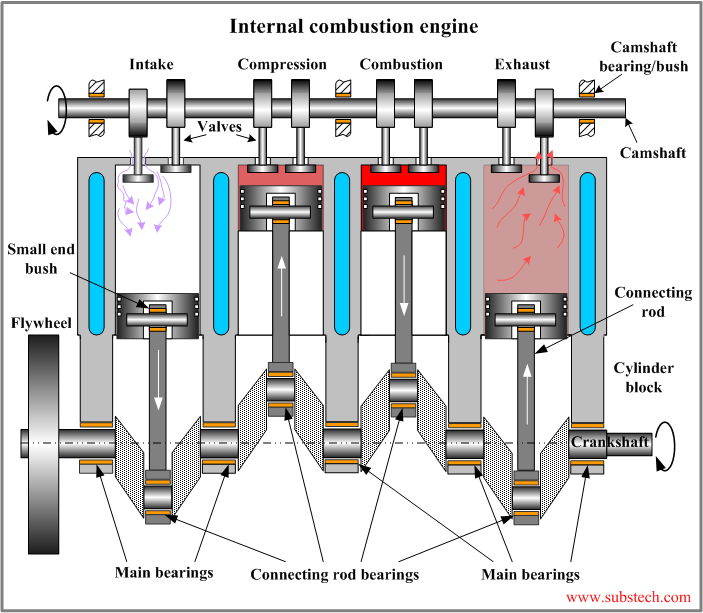

2 stroke connecting rod failure. The following proper maintenance can minimize bolt failure. It converts the linear motion of the pistons to the rotary motion of the crankshaft. We will be highlighting three special tools. Bolt surface and threads must not be damaged by rough handling.

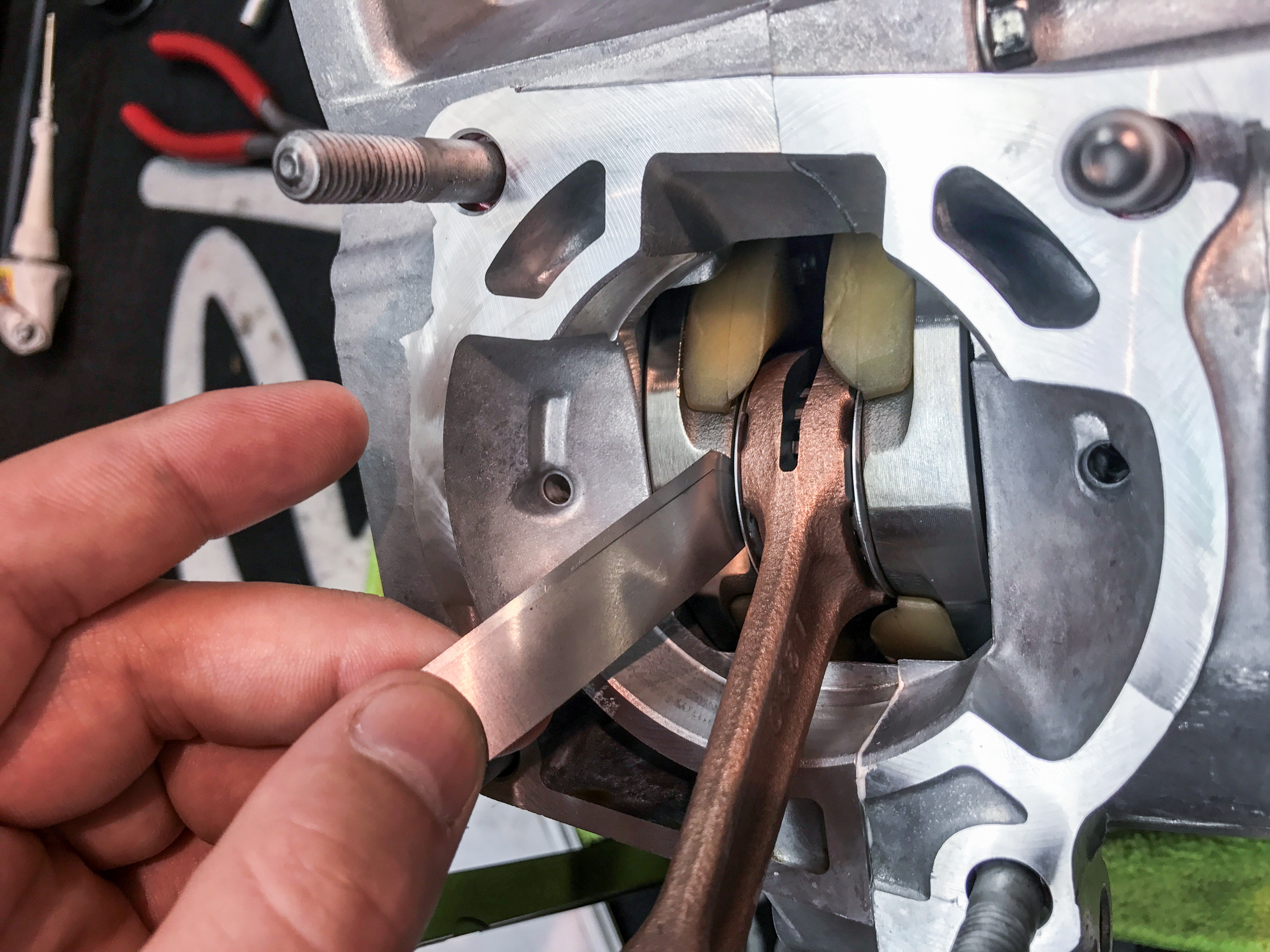

The bolt is given a good surface finish to reduce stress raisers. This video will show how to rebuild a two stroke crankshaft. The connecting rod connects the pistons to the crankshaft. This is video to remove crankshaft bearing without hammer https youtu be zb9sqod9blg check this video installation connecting rod kit without hummer https.

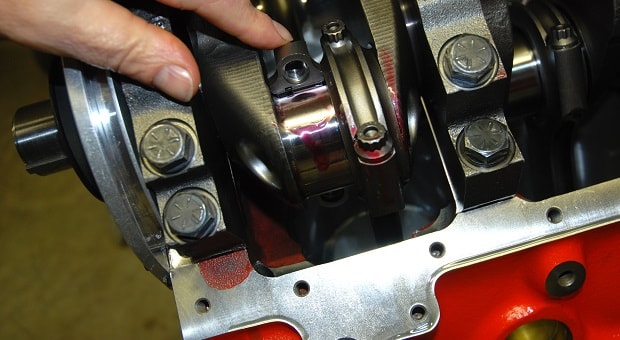

The connecting rod is required to transmit the compressive and tensile forces from the piston and rotate at both ends. The ends of the rod spin around the crankshaft and the wrist pin of the piston. The connecting rod is fastened around the crankshaft on one end and to the piston on the other end. Either way the engine is going to need a new rod.

Cast rods are more brittle than forged or billet rods and will often break when this happens. Connecting rod with its parts minimizing the failure of connecting rod bolts by proper maintenance. As the crankshaft turns the rod also turns forcing the piston up and down. Two from k l and one from ktm.

The connecting rod can fail due to many reasons e g. Some two stroke engines are designed with the transmission side main bearing on the outboard side of the main seal so that it s oiled by gearbox lube but otherwise the rod big end is oiled by the fuel oil mix. A connecting rod also called a con rod is the part of a piston engine which connects the piston to the crankshaft together with the crank the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. On every stroke the connecting rod is stretched and compressed.

A bad rod or rod bearing will eventually destroy an engine. The broken rod can go through the. Forged and billet rods are more ductile and will usually bend or buckle rather than break.