2 Part Moisture Remediation For Concrete Floors

When the concrete is curing it takes time for moisture to escape but construction time constraints and deadlines can leave concrete without adequate drying time.

2 part moisture remediation for concrete floors. Moisture remediation concrete protects surfaces from freeze thaw damage reduces dusting of concrete and increases coating life by as much as 300. Concrete science is still evolving. Concrete is visually dry and porous resistant to chemical loadings for interior and exterior use applications to suppress moisture on unheated moisture resistant porous concrete with residual moisture up to 100 rh or 25 lbs 1000 sq ft 24 hrs. While the industry doesn t have all the answers it can be said that moisture issues in concrete floors tend to arise from one of two sources.

Part of that process requires testing your slab for moisture content and read more. Apf s vaporsolve moisture remediation systems are highly specialized epoxy coating systems formulated to isolate moisture sensitive flooring from all levels of concrete moisture. Vaporsolve systems are used when concrete has a known moisture problem when concrete dries too slowly to meet the construction schedule and as a preventative measure when concrete doesn t have a vapor retarder. However construction deadlines and time constraints may leave concrete without enough time for drying.

If you catch the problem early you may only have to replace a few tiles or. Remember these flooring problems are costing the industry 2 4 billion on remediation of concrete slab and floor coverings as a result of moisture related flooring failures. Surface preparation must be sufficient to allow pene krete to penetrate the surface. Floor moisture and moisture vapor can be cause for concern whether the slab is newly poured or many decades old and regardless of location.

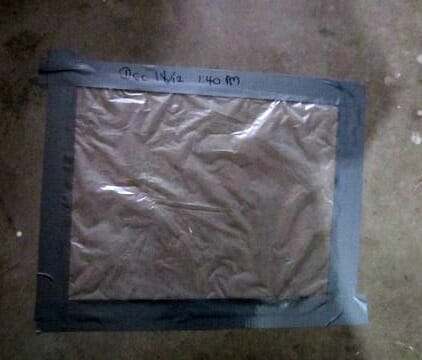

Before applying schönox underlayments prior to installing flexible coverings as well as wood floor. The floor repair estimate from remediations ranges from as little as 200 to 20 000 or more. Regular conditions will require 120 180 days. 2 coats 12 lbs per the astm f1869 calcium chloride test method and 85 rh per the astm 2170 relative humidity test.

1 coat 8 lbs per the astm f1869 calcium chloride test method and 80 rh per the astm 2170 relative humidity test. This system is applied at 16 mils over concrete. Even pan poured upper level floors can create moisture problems if sufficient curing time isn t allotted. How to prevent moisture.

As the concrete cures it ll take time for the moisture to escape. Vaporsolve 100 lp system is a specially formulated 100 solids epoxy coating designed to comply with astm f 3010 and is for use over concrete with high moisture levels for the purpose of isolating the concrete from moisture sensitive flooring. Whether used as a subfloor or top layer it can provide facilities with an extremely durable and long lasting application when tested and installed correctly.